Brochure Lamination

Brochure Lamination - This process involves applying a thin transparent plastic film over. Common types of laminate are gloss, matt, velvet, gold, and. Many print projects have a clear laminate applied as a finishing step. Dive into the world of printing with our clear explanation of lamination. It's done for decoration, for protection or to make printed material more durable. Create a brochure that truly shines with laminated booklet printing; Lamination is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. Lamination is a crucial finishing technique applied to brochures, providing them with enhanced durability and visual appeal. Luxurious laminations available to create premium glossy booklet printing; Understand why lamination is a crucial finishing touch for durability and aesthetics, and how it can protect and enhance. It's done for decoration, for protection or to make printed material more durable. The lamination finishing process involves adding a thin plastic layer to paper or card sheets to improve and safeguard the printed content. It protects the paper from ordinary wear and tear and extends the life of the printed item. Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. Lamination is the process of adding a clear plastic coating to printed matter. Understand why lamination is a crucial finishing touch for durability and aesthetics, and how it can protect and enhance. Made of durable plastic film, laminates protect the paper and ink against dirt and moisture. This process involves applying a thin transparent plastic film over. Lamination is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. Create a brochure that truly shines with laminated booklet printing; The lamination finishing process involves adding a thin plastic layer to paper or card sheets to improve and safeguard the printed content. Common types of laminate are gloss, matt, velvet, gold, and. Lamination is the process of creating several layers in a material. It protects the paper from ordinary wear and tear and extends the life of the printed item.. It protects the paper from ordinary wear and tear and extends the life of the printed item. This process involves applying a thin transparent plastic film over. Many print projects have a clear laminate applied as a finishing step. Understand why lamination is a crucial finishing touch for durability and aesthetics, and how it can protect and enhance. Lamination is. Lamination is the process of creating several layers in a material. Many print projects have a clear laminate applied as a finishing step. Dive into the world of printing with our clear explanation of lamination. Download our brochure templates to help. Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both. This process involves applying a thin transparent plastic film over. This protective layer safeguards the material. It's done for decoration, for protection or to make printed material more durable. Common types of laminate are gloss, matt, velvet, gold, and. Lamination is the process of adding a clear plastic coating to printed matter. Understand why lamination is a crucial finishing touch for durability and aesthetics, and how it can protect and enhance. Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. The lamination finishing process involves adding a thin plastic layer to paper or card sheets to improve. The lamination finishing process involves adding a thin plastic layer to paper or card sheets to improve and safeguard the printed content. Needs & benefits of laminating digital & paper prints. Luxurious laminations available to create premium glossy booklet printing; It's done for decoration, for protection or to make printed material more durable. Common types of laminate are gloss, matt,. It protects the paper from ordinary wear and tear and extends the life of the printed item. Download our brochure templates to help. Luxurious laminations available to create premium glossy booklet printing; Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. Lamination is the process. Lamination is the process of creating several layers in a material. Many print projects have a clear laminate applied as a finishing step. Luxurious laminations available to create premium glossy booklet printing; Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. Made of durable plastic. Download our brochure templates to help. Dive into the world of printing with our clear explanation of lamination. Lamination is the process of adding a clear plastic coating to printed matter. Lamination is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. Needs & benefits of laminating digital. Download our brochure templates to help. Lamination is the process of adding a clear plastic coating to printed matter. This process involves applying a thin transparent plastic film over. It's done for decoration, for protection or to make printed material more durable. Lamination is a crucial finishing technique applied to brochures, providing them with enhanced durability and visual appeal. Gloss and matte are typical types of. This protective layer safeguards the material. Create a brochure that truly shines with laminated booklet printing; Dive into the world of printing with our clear explanation of lamination. Download our brochure templates to help. Understand why lamination is a crucial finishing touch for durability and aesthetics, and how it can protect and enhance. Made of durable plastic film, laminates protect the paper and ink against dirt and moisture. Lamination is the process of adding a clear plastic coating to printed matter. Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. Needs & benefits of laminating digital & paper prints. The lamination finishing process involves adding a thin plastic layer to paper or card sheets to improve and safeguard the printed content. Lamination is a crucial finishing technique applied to brochures, providing them with enhanced durability and visual appeal. It's done for decoration, for protection or to make printed material more durable. This process involves applying a thin transparent plastic film over. Many print projects have a clear laminate applied as a finishing step. It protects the paper from ordinary wear and tear and extends the life of the printed item.Glossy Lamination Promotion Magazine/Catalogue/Booklet Printing, A4

Matt lamination brochure/laminated brochure printing service

Bi Fold Brochures, Bi Fold Brochure Printing in Saigon Helixgram

Best Brochures catalogues printing Hyderabad pixeleffect.in

Fast&Few Gloss Laminated Brochures US

Matte Lamination Spot UV Soft Cover Perfect Binding Professional Custom

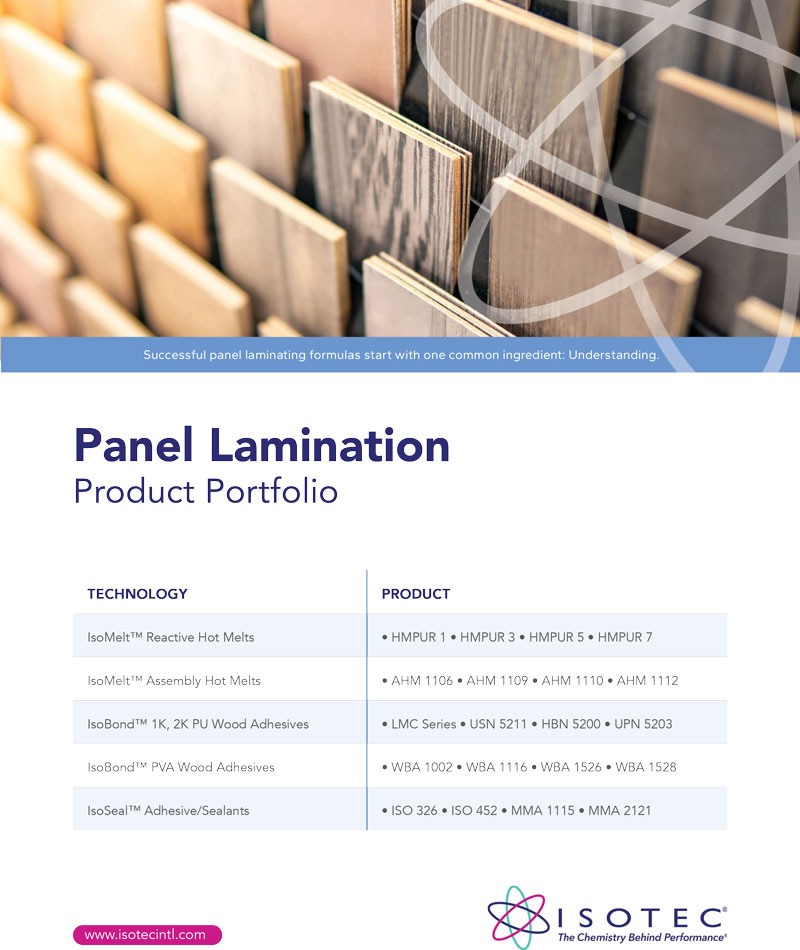

Brochures Isotec

Downloads i2 Europe Technical Machinery Solutions

Leading brochures printing company in Delhi Brochure Printing services

Brochure printing in Munirka, brochure printing Delhi NCR INDIA

Lamination Is The Process Of Applying A Thin Layer Of Plastic To Paper Or Card Sheets To Enhance And Protect The Printed Matter.

Common Types Of Laminate Are Gloss, Matt, Velvet, Gold, And.

Luxurious Laminations Available To Create Premium Glossy Booklet Printing;

Lamination Is The Process Of Creating Several Layers In A Material.

Related Post: